Laser Cleaning

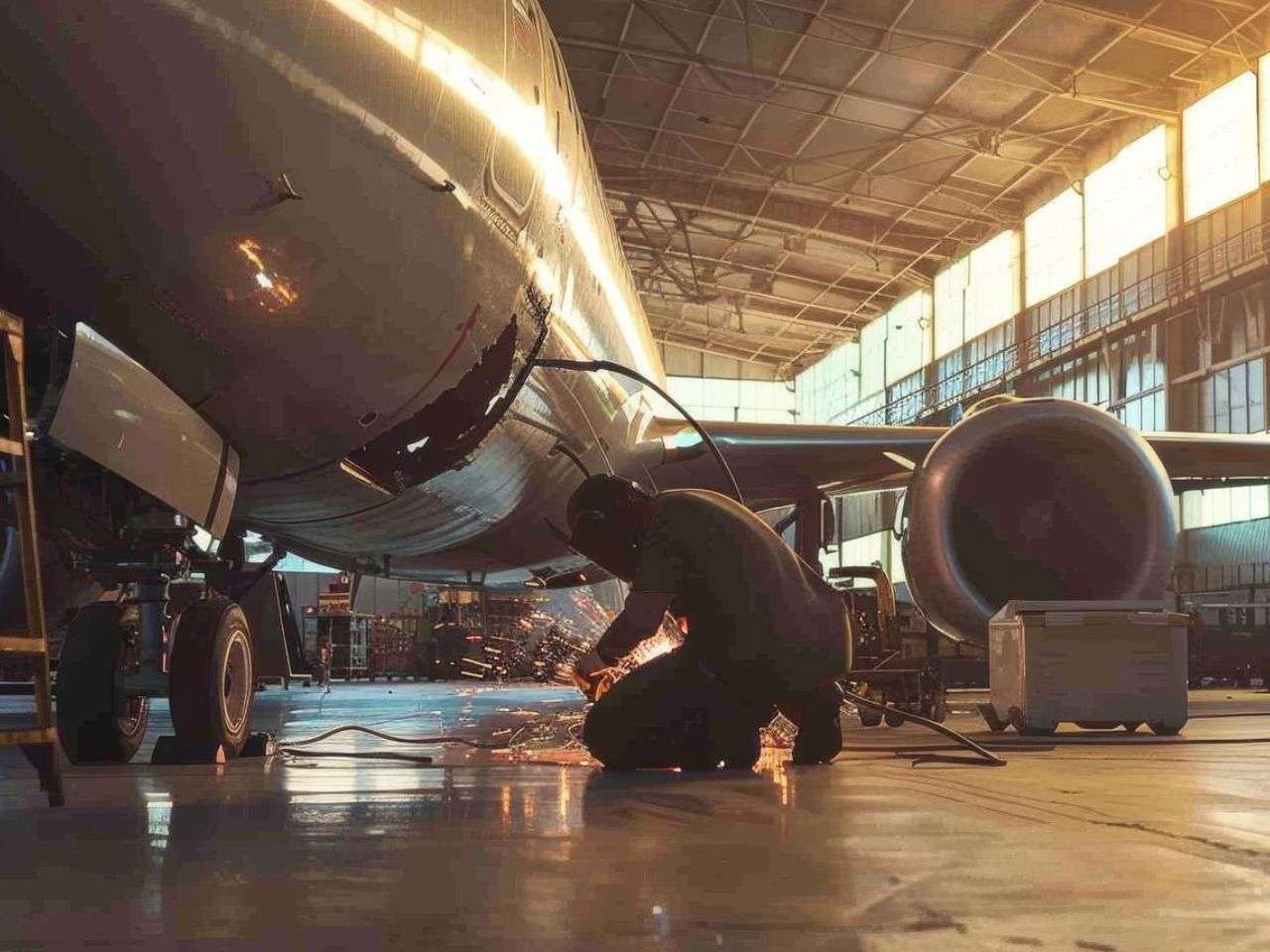

Advanced Material Processing for Aerospace

with Precision Laser Solutions

System has over 40 years of experience working with large aerospace companies. Our "engineered approach" ensures the highest grade of solutions necessary for commercial air travel. We provide precise, efficient, and eco-friendly methods for removing coatings, contaminants, and oxidation. We can deliver comprehensive solutions including custom mobile workspaces, safety programs, and Laser Safety Officer training that meets OSHA requirements.

Aerospace Maintenance Experts

Laser Cleaning Precision

Rust Removal Solutions

Industry Standard Compliance

laser partnerships

Paint and Coating Removal

Surface Preparation for Repainting: Laser cleaning ensures the surface will be clean and uniform without any micro-abrasions so that the surface can be painted or coated.

Selective Coating Removal: With our advanced technology and precision settings, it is possible to remove surface layers without damaging the substrate.

Oxide and Corrosion Removal

Oxide Layer Removal on Metals: With laser cleaning, oxidation can be removed from turbine blades, landing gear components, and other metal structures around the wind turbine by removing oxidation.

Corrosion Removal on Aluminum and Titanium: Aluminium and titanium are commonly used in the aerospace industry and are easily cleaned with lasers to remove corrosion, clean surfaces, and inspect welds.

Component Cleaning and Maintenance

Clean Surfaces for Bonding and Adhesion: During the process of bonding or sealing, laser cleaning ensures excellent adhesion between surfaces without introducing any contaminants into the process.

Precision Cleaning for Sensitive Parts: For electronic components, sensors, and many other delicate components, it is essential the surfaces are clean and free from contamination.

Custom Training and Safety Programs

Laser Operator Training: The lasers used in industrial environments are Class IV Lasers and can cause serious injury. To be in compliance with OSHA, each operating entity must have a designated Laser Safety Officer who has undergone training and received official certification.

We have the best training and certification programs for Laser System Operators and Laser Safety Officers. We can enroll your staff in to a self-paced online program that will test and certify your staff.

Laser cleaning requires operator training to ensure safety and efficiency. A technician learns how to adjust high-powered laser setups according to the type of material and the level of contamination. As a result, precision, safety, and optimal performance are ensured while risks are minimized.

Service and Support: A laser manufacturer’s service and support are crucial for smooth operation. An effective training program prepares operators to use equipment confidently, while dedicated customer support ensures quick troubleshooting. You can extend the lifespan of your laser cleaning system by getting reliable assistance that minimizes downtime, enhances efficiency, while reducing downtime.

Efficient and Sustainable Laser Cleaning Solutions

Precision, eco-friendly maintenance methods, and reduced downtime for seamless operations to improve aerospace maintenance. We provide solutions that enhance efficiency and ensure safety. With our comprehensive solutions you can rest assured knowing your solution is tailored to your needs and complies with OSHA standards.

On-Site Maintenance Efficiency

The use of laser cleaning reduces aircraft downtime by streamlining on-site processes and making minimal disassembly necessary.

Eco-Friendly Cleaning Standards

Sustainability requirements in aerospace can be met by reducing waste generated by abrasive or chemical cleaning methods.

Enhanced NDT Surface Preparation

Ensures clean, contaminant-free surfaces for precision inspections on aircraft, improving safety and reliability in the maintenance process.

Costs and Scalability

Energy and Maintenance Costs

Initial Investment:

Laser cleaning is cost effective. There is less setup and cleanup than traditional cleaning methods and it eliminates consumables like chemicals and abrasives. Laser systems can last over 400,000 hours and require fewer replacements and lower maintenance costs.

Ongoing Value:

Laser systems provide outstanding value over the life of the machine. With proper. care and maintenance, our machines will last many years of hard, industrial use.

Cost and Return on Investment (ROI)

Operational Efficiency:

Laser cleaning generally uses less energy compared to abrasive or chemical cleaning methods. However, the power supplies required to operate these systems can be substantial, which may impact overall energy consumption.

ROI:

The return on investment is best measured with faster production, reduced cost of use and reduction in exposure and waste disposal for contaminates.